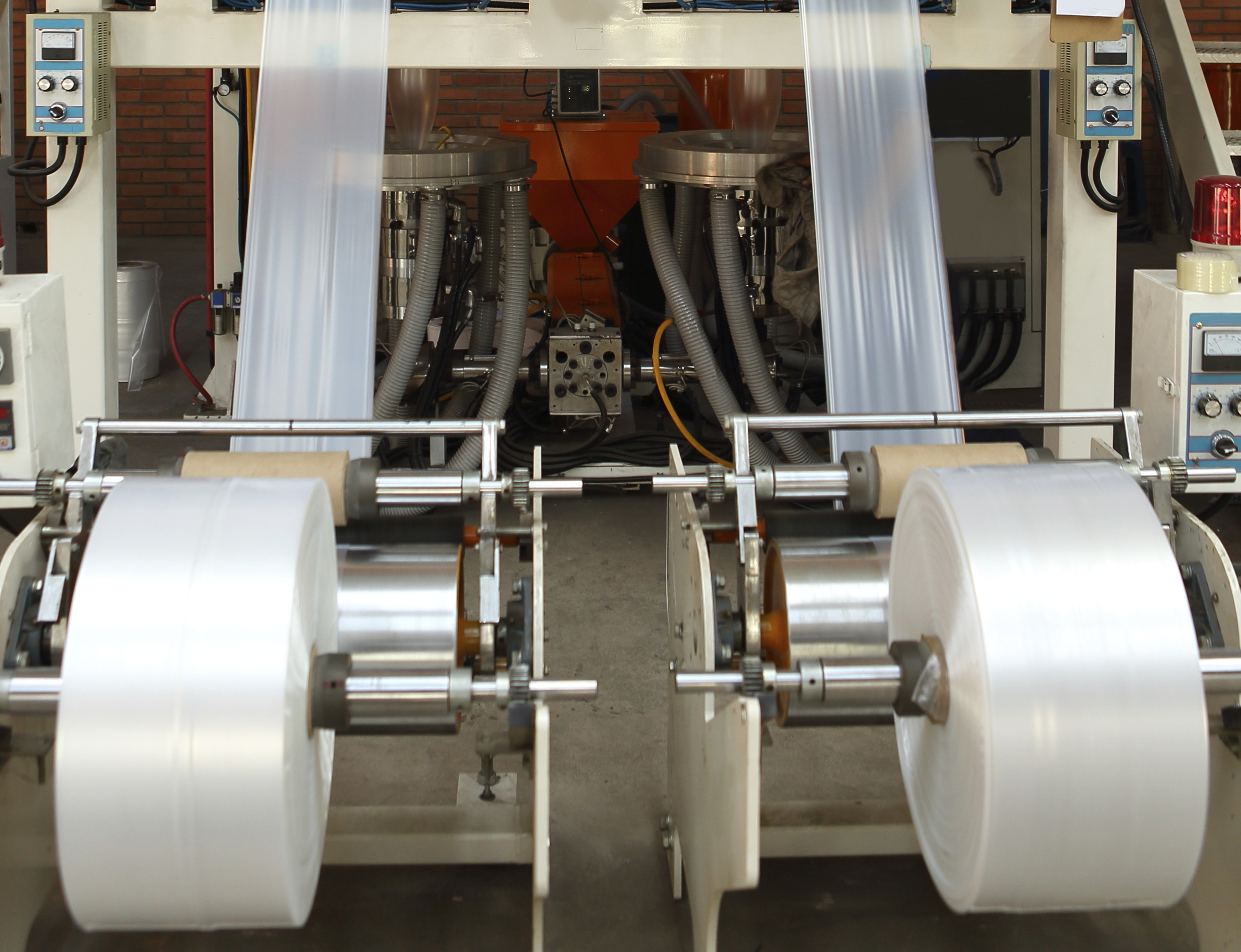

BöttcherTec Rollers:

Tailor-made for each process step

Böttcher offers a broad range of rubber and polyurethane roller covering compounds, covering practically all areas in the production and converting of plastic film. This range is continually developing and expanding to keep pace with the changing demands of the industry. For example, besides classic rubber compounds for film extrusion, we also manufacture extremely wear-resistant polyurethane coverings. These compounds significantly extend the life of the rollers, thereby having a positive effect on machine up-time and extending the range of different materials, web widths, etc. which can be produced. For PVC processing, e.g. for floor coverings, you can choose from a range of different compounds, depending on your specific requirements in terms of temperature and chemical resistance.

For coating and other finishing processes, BöttcherTec coverings are in use all over the world, thanks to the optimized compatibilty of our coating roller coverings with all types of coating materials. This guarantees even and consistent coating weights across the width of the film and throughout the run, and in many cases, thanks to the resulting dimensional and hardness stability of the roller coverings, enables a reduction in coating weight without detracting from the properties of the finished product. In both flexographic and gravure printing on plastic film, BöttcherTec roller compounds excel with uniform and consistent ink transfer and print quality, whether you are printing solids, screens or both.

Service and support

- Service and technical support by Böttcher field personnel

- Support in the selection of the best roller materials for your specific needs

- Compatibility testing of process chemicals in Böttcher’s laboratories

- Support in sizing roller crowns and other dimensions

- Re-grinding and profiling of roller coverings

Extended roller life

- Reduced long-term deterioration of mechanical and dynamic properties

- Excellent resistance to edge marking and cutting

- Less downtime, enhanced flexibility

Optimized materials for each process step

- Blown and flat film extrusion, extrusion coating and laminating

- Pressure rollers and embossing counter rollers PVC processing

- Coating and laminating, flexo and gravure printing

- Contact rollers for winders

- Tensioning, guide and transport rollers in a wide range of durometers

Deutsch

Deutsch

Français

Français

Český

Český

Español

Español

Polski

Polski